About Us

VISCOSMO Co., is exporter & distributor of HANSOL Transfer paper and we have developed the quality of dye sublimation transfer paper in partnership with them. We are manufacturing and converting HANSOL transfer paper with various size and length for the global digital textile printing market. The strong forte of our paper is that it always has stable quality assurance to our customers in overseas market. To do this, we always welcome you to test our dye sublimation transfer paper with a variety printing solutions along with them.

Thank you

Transfer Papers Sublimation Printable

What Is Sublimation Heat Transfer Paper?

HANSOL Sublimation heat transfer paper is used in the dye-sublimation printing process for applying images to specially coated ceramics, metals or polyester. When heated, the ink converts from a solid into a gas, skipping the liquid phase.

Sublimation paper used, as heat transfer paper in dye-sub printing is not coated like the receptor surface.

It has a special finish that prevents the ink from soaking into the paper.

After the paper is printed with the transferable image, it is placed on the coated surface of the receptor product to be imprinted with heat and pressure from a heat press.

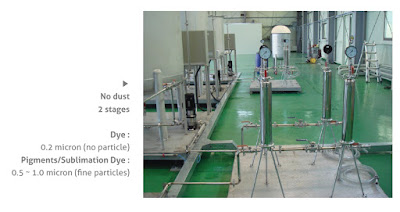

Paper Properties

Sublimation heat transfer paper comes in widths of 24 to 63 inches. High-release dye-sub heat-transfer paper has a silicate coating applied in vertical grids to hold the ink. During printing, heat from the press evaporates or sublimates the ink into a gas form.

The released ink vapor then bonds with the surface of the receptor material to form a permanent print.

HOW TO USE Sublimation heat transfer Paper?

HANSOL Sublimation heat transfer paper is coated with a special chemical that transfers any printed images on the paper to another material or surface when placed under heated pressure.

Such paper is popular for among individuals who want to place logos, pictures and other printed graphics on clothing.

Processing

Applications of it in industry & Especially application on textile materials

Digital Textile System

Features

You could make a small quantity and could easily complement many different inquiries.

You could substantially save cost for your business

– No need to inquire a large inventory cost

– The Heat Transfer System only requires

a computer, a printer, sublimation ink, materials and a specialized Heat Transfer System machine.

You could utilize the Heat Transfer System due to its short processing time.

The brightness and the coolness of dye sublimation ink are not easily be decolorized, which give the users advantages.

Requirement

Printer

Any standardized desktop or large format printer, which uses dye sublimation ink.

Ink

Specialized dye sublimation ink, which can withstand heat up to 300 degrees in Celsius. .

Process

Printing with sublimation ink on the sublimation paper or other specialized paper. Material uses that put on the heat transfer machine, which are heat transfer after printing. In 40seconds or up to 3Minutes, you can get very nice print out. Normal temperature on the towel, clothes, T-shirts, etc. is only 40~45 seconds and recommend 190 degrees in Celsius.

Basically dye sublimation ink cannot use on the 100% Cotton or natural materials.

For example, to make heat transferred on T-Shirt, it has to be includes more than 50% of Cotton. Good cloths are 100% of polyester yarn. In addition, Always, heat transferring available on the coated materials such as coated steel, Coated aluminum, plastic and wood etc.,

Quality Profiles

Quality

Product line for safety

Keep in produce safety coated goods

No Up & Down quality

Compatibility of any types of ink & print

Balanced develops color

Guarantee

There is NO Up & Down quality of Hansol Product

Strength = Every types of ink & Printer can set with Hansol paper

Weakness = For develop the deep dark color is necessary experience of technic.

Ex. Profile print setting

Benefits

HANSOL SUBLIMATION TRANSFER PAPER is much more common product. As everyone knows, European products are really excellent quality with High price.

HANSOL product is little less quality than Europa product. But, production goods from our paper that sells all over World fashion place. It means, our product have possibility.

Europe's sublimation paper set by high viscosity ink uses.

Which requires, High Quality = High Cost

On the other hand, HANSOL paper is not set by exact ink and printer uses.

Every type of ink that could makes effect well with transfer.

Good quality = High Cost Save

HANSOL product have sufficient competitive for the future of view.